hotline

13917550119UV glazing oil not used or less organic solvent, low VOC emissions, high efficiency and wide substrates, film-forming performance, become one of the best protective film printing ink adornment layer, get a lot of application in many fields. UV light oil was applied to printing film layer, which can effectively improve the pattern of transfer printing gloss, resistance and wear resistance increase printing film, such as performance, at the same time increase the aesthetic of the product and use value.

At present, the UV transfer film has the following problems in actual use:

1. Continuous production cannot be realized.

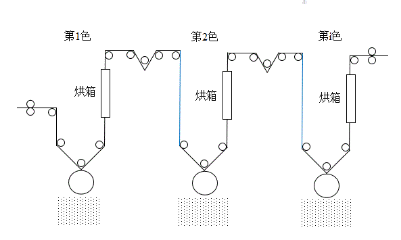

Sublimation spent membrane usually use intaglio color printing overprint technology implementation, as shown in figure 1, the base layer by the first coating head 1 color printing ink, and then through the oven to dry, in into the second coating head 2 color printing ink. FIG. 1 is a schematic diagram of gravure printing. Heat transfer printing film printing USES solvent acrylic resin as raw material, through the oven to produce heat to evaporate the solvent to become film, so can realize multi-color overprinting continuous production. The UV printing layer of the conventional UV transfer film can not be dried through the oven. Only through UV curing can the film be dried. For continuous printing, you need to in the oven and a coated head after the space between the location (blue line) curing device installed, the space is little, but the gap is not suitable for installing large volume mercury lamp curing device; Although the installation space of the LED curing device is small, for the transfer film that needs to be printed with multi-layer UV layer, it means that several sets of LED curing devices need to be installed to increase the cost.

2. It is difficult to reprint the surface of conventional UV layer.

In order to improve the protection level of UV protection layer, it is usually used to improve the spatial density of the protective layer after the protection of the protective layer. The increase of UV coating density will affect the printing of ink layer on the UV protection layer; In addition, in the process of transfer printing, the "concave" corner bit will appear because the coating is hard to get rid of the cracking phenomenon.

Can overprint UV LED curing/transfer printing varnish, the light oil under heating conditions of crosslinking reaction, realize the resin composite heat curing film, the film surface drying, solvent resistance, good flexibility, good light curing characteristics. Protective layer on the protective layer can continue printing or printing ink, because of the protective layer contains no curing acrylic acid groups and unsaturated double bond or epoxy groups, can be crosslinked with the upper cover or printing ink, thus improve the upper cover or ink adhesion on the protective layer. Printing design is all good, or moved to the product after light oil layer is still the thermoplastic and light curing characteristics, at this time, after UV/LED light, acrylic acid groups and unsaturated double bond or epoxy groups on the free radical light curing initiator under the function of free radical polymerization, form the three-dimensional network polymer structure, improve the protective layer properties such as hardness, resistance and abrasion resistance.